Rubber Bushings, Moldings, Seals, and Gaskets: The Cornerstones of Industrial Applications

Rubber products, in their various forms, are indispensable components across countless industries. From the automotive sector to aerospace, from construction to electronics, rubber products play a crucial role in ensuring optimal performance, durability, and safety. Lusida Products is a leading provider of high-quality rubber bushings, moldings, seals, and gaskets, catering to diverse industry needs.

Rubber Bushings: The Shock Absorbers

Rubber bushings are essential components that absorb shock and vibration, reducing wear and tear on machinery and equipment. They are typically made from a combination of rubber and metal, providing flexibility, durability, and strength.

Key applications of rubber bushings:

· Automotive suspension systems

· Industrial machinery

· HVAC systems

· Electrical equipment

Benefits of Lusida’s rubber bushings:

· Superior vibration isolation

· Enhanced noise reduction

· Increased equipment lifespan

· Customized solutions to meet specific requirements

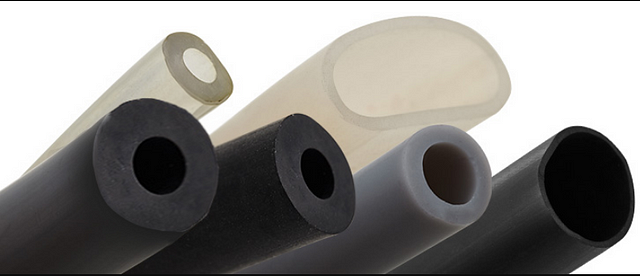

Rubber Molding: Precision and Versatility

Rubber molding is a versatile process used to create a wide range of rubber components with intricate shapes and designs. Lusida Products specializes in producing high-precision rubber moldings that meet the exacting demands of various industries.

Common rubber molding processes:

· Injection molding

· Compression molding

· Extrusion molding

· Transfer molding

Applications of rubber moldings:

· Automotive components (seals, gaskets, hoses)

· Industrial seals and gaskets

· O-rings and washers

· Medical and pharmaceutical components

Benefits of Lusida’s rubber moldings:

· Consistent quality and precision

· Wide range of rubber compounds

· Rapid prototyping and production

· Cost-effective solutions

Rubber Seals: Preventing Leaks and Contaminants

Rubber seals are critical for preventing leaks, contaminants, and environmental ingress. Lusida Products offers a comprehensive range of rubber seals designed to meet diverse sealing requirements.

Types of rubber seals:

· O-rings

· Static seals

· Dynamic seals

· Custom-engineered seals

Applications of rubber seals:

· Automotive engines and transmissions

· Hydraulic and pneumatic systems

· Food processing equipment

· Aerospace components

Benefits of Lusida’s rubber seals:

· Excellent sealing performance

· Wide range of materials and compounds

· Custom-designed solutions

· Resistance to various environmental conditions

Rubber Gaskets: Creating Reliable Seals

Rubber gaskets are used to create a seal between two surfaces, preventing leakage of fluids or gases. Lusida Products provides a variety of rubber gaskets to suit different applications and industries.

Types of rubber gaskets:

· Die-cut gaskets

· Molded gaskets

· Extruded gaskets

· Custom-designed gaskets

Applications of rubber gaskets:

· Automotive engine and transmission

· Plumbing and pipe fittings

· Industrial equipment

· Appliances

Benefits of Lusida’s rubber gaskets:

· Superior sealing performance

· Wide range of materials and compounds

· Custom-designed solutions

· Resistance to various environmental conditions

FAQs

Q: What factors should I consider when selecting a rubber material for my application?

A: The choice of rubber material depends on factors such as temperature range, chemical resistance, hardness, and elasticity. Lusida’s experts can help you select the right material for your specific needs.

Q: Can Lusida Products provide custom rubber components?

A: Yes, Lusida Products offers custom design and manufacturing services to meet specific requirements. Our engineering team can work with you to develop the ideal solution.

Q: What industries do Lusida Products serve?

A: Lusida caters to a wide range of industries, including automotive, aerospace, industrial, medical, and food processing.

Q: How can I ensure the quality of rubber components?

A: Lusida is committed to quality and adheres to strict quality control standards. We offer various testing and inspection services to guarantee product performance.

Q: What is the lead time for custom rubber products?

A: Lead times vary depending on the complexity of the product and order quantity. Lusida strives to meet customer deadlines while maintaining high quality standards.

By partnering with Lusida Products, you can access a wide range of high-quality rubber components tailored to your specific needs. Our expertise, combined with advanced manufacturing capabilities, ensures that your applications benefit from optimal performance and reliability.

Comments

Post a Comment